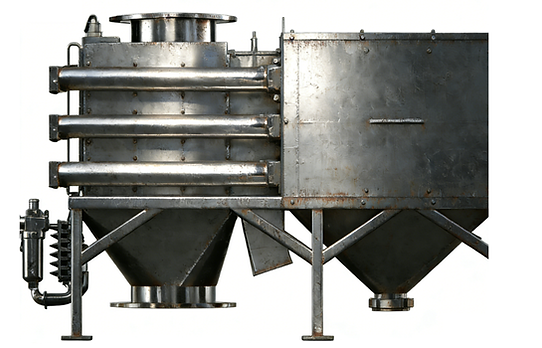

Pneumatic self-cleaning drawer type iron separator

● Working principle

Based on the manual drawer-type magnetic separator, an automatic cleaning mechanism is added. Controlled by a PLC, the cleaning system can be programmed to set the frequency and interval for iron removal based on the iron content. The system automatically performs impurity cleaning at the set times without manual intervention. Compared to manual iron removal types, the automatic cleaning model enables continuous operation of the production line.

● Structural features

-

Allows continuous feeding, ensuring uninterrupted production line operation.

-

Unique enclosed design of the iron discharge area prevents powder leakage in both positive and negative pressure conditions.

-

Simple, durable scraper-and-ring design, easy to disassemble, maintain, and clean.

-

Special non‑metallic scraper rings with effective iron removal and long service life.

-

Smooth operation of the slide mechanism with adjustable speed.

-

Magnetic system equipped with a protective cover for added safety and to prevent foreign objects from entering.

-

Customizable layer configurations to meet user needs as much as possible.

-

Optional vibrator for materials with poor flowability, increasing processing capacity.

-

Equipped with synchronous and asynchronous iron discharge functions for flexible adaptation to different working conditions.

-

Audible alarm via a buzzer in case of abnormal conditions to avoid process defects.

-

Material flow path can be coated with ETFE, PTFE, or nano‑ceramic spray.

● Parameters